Views: 150 Author: Site Editor Publish Time: 2021-03-11 Origin: Site

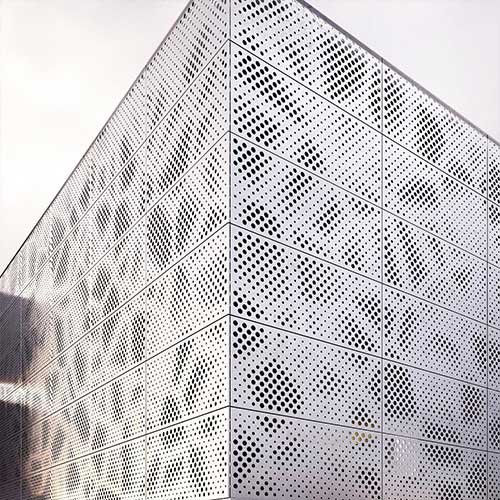

Aluminium Perforated Metal Mesh also called aluminum perforated panel, is made of aluminum plate or aluminum alloy plate through CNC stamping or laser cutting process.It can be manufactured into a variety of hole sizes, shapes and patterns for all kinds of cutting-edge design concepts. As a manufacturer, we can provide full gauges of aluminum plates to meet your different adornment demands.

Specifications of Aluminium Perforated Metal Mesh:

Material: 1060 aluminum, 3003/5005 aluminum alloy.

Thickness: 0.3–12 mm.

Width: 0.8–1.22 m.

Length: 1.2–2.44 m.

Hole Diameter: 5–100 mm.

Hole Arrangement Mode: straight, staggered.

Staggered Center: 0.125–1.875 mm.

Mesh Opening Area: 7% – 83%.

Fabrication Methods: welded or lock seam.

Surface Treatment: standard, anodic oxidation, powder coating or fluorine carbon spraying.

Standard: ASTM B209.

Features of Aluminium Perforated Metal Mesh:

Very versatile

Naturally lightweight and easy to work with

Highly resistant to corrosion

Cost-efficient material

Durable and long-lasting

Applications of Perforated Aluminum Sheet Metal:

Ideal for indoor and outdoor structures

Decorative surfaces

Architectural elements

Noise-resistant walls and ceilings

Acoustical panels for sound control

Sunshades to control light

Privacy applications

Air diffusers for HVAC equipment

Tips for Perforated Aluminum Panels

Our options vary by style and pattern. Accurate Perforating can craft perforated aluminum sheet metal so that the holes are perfectly customized to your project. Using special software and perforating techniques, we can create moving and flowing images in the perforated aluminum panels for compelling building facades. We offer standard straight-line designs as well as staggered to give the unique look, feel and functionality you require. We can cut varying hole sizes for the perfect perforated aluminum sheet.